For investors in photovoltaic power plants, every additional kilowatt hour of electricity generated by the power plant generates an additional kilowatt hour of income, as the power generation of the power plant directly affects the investment return cycle. Therefore, the most important concern for investors is the power generation of the power plant. The power generation of a photovoltaic power station can be affected by many factors, such as the quality of photovoltaic modules, inverters, cables, installation orientation and inclination angle of modules, dust and shadow obstruction, photovoltaic module inverter ratio system scheme, grid quality, etc.

The impact of shadow occlusion on power generation

Among the many factors that affect the power generation of photovoltaic power generation systems, shadow shading is a common one. Common shading mainly includes power poles, trees, guardrails, bird droppings, dust, and front and rear row shading of components.

During the construction process of many power plants, it is often impossible to completely avoid shadows, and many people may feel that the shadow area is small and will not have a significant impact. In fact, if some components or a single component are obstructed, the entire string of components will be affected, which is the barrel effect of a series circuit. In a string of components, each current is the same, and the maximum current is determined by the smallest component. So as long as one component is obstructed, it will affect the output power of the entire string. Severe cases can also cause hot spot effects on components, reducing their power generation efficiency and service life, and even leading to local burning of components, posing certain safety hazards. So it is not only necessary to avoid shadow obstruction during power plant design, but also to pay attention to post operation and maintenance, and regularly clean components.

The impact of system capacity ratio on power generation

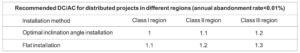

Capacity ratio refers to the ratio of the installed capacity of a photovoltaic system to the rated capacity of the inverter. If the photovoltaic system is designed with a 1:1 capacity ratio, and the output power of the photovoltaic modules cannot reach the nominal power, it will waste the capacity of the inverter. At present, super configuration design is commonly used to improve the comprehensive utilization rate of photovoltaic systems, reduce the cost of electricity per kilowatt hour, and increase the revenue of power plants. But this does not mean that the capacity ratio can be infinitely expanded to save inverter investment, because the cost of inverters accounts for only about 5% of the entire photovoltaic system. Overloading not only is not cost-effective, but also leads to limited operation of inverters, resulting in loss of power generation. Therefore, designing a reasonable system capacity ratio is beneficial for improving the economy of photovoltaic power generation systems. In regions with different types of resources, due to varying solar energy resource conditions and temperature characteristics, calculations need to be based on the specific local conditions. The following are recommended capacity ratios for different regions.

The impact of improper cable selection on power generation

If the inverter is compared to the brain of a photovoltaic power station, the cable is the nervous system of the photovoltaic system, connecting photovoltaic modules, inverters, combiner boxes, grid cabinets and other equipment in series to form a whole. Therefore, reasonable cable selection is crucial for the entire photovoltaic system.

When selecting cable design, it is important to choose the appropriate wire diameter, especially for large photovoltaic power plants that occupy a large area and have long lines. If the AC cable diameter is too thin, it can cause cable overload and heating, which not only affects power generation but also poses safety hazards such as short circuits and fires. Another point to note is that for cables with the same current carrying capacity, aluminum cables have a much larger cross-sectional area than copper cables, so it is necessary to consider whether the inverter AC end can be connected.

The AC output side of the inverter is designed based on copper wire standards, and it is recommended to use copper core cables. However, using aluminum core cables can save some investment costs compared to copper core cables, so many installers will use aluminum core cables. But it is necessary to use copper aluminum transition terminals that meet the standard requirements, because copper aluminum joints are prone to electrochemical corrosion, causing poor contact between copper and aluminum, increasing resistance, and affecting the efficiency of the entire photovoltaic system. Long term operation can cause the temperature of the joint to rise, accelerate corrosion, and even burn out.

The selection of cables has a direct impact on the power generation of photovoltaic power plants. Choosing the appropriate cable type, specifications, and cables with good load capacity, weather resistance, and durability can minimize energy loss, improve power generation efficiency, ensure the normal operation of photovoltaic power plants, and maximize power generation.

The impact of grid power quality on power generation

The power quality of the power grid includes voltage deviation, current deviation, frequency deviation, voltage fluctuation or flicker, three-phase imbalance, temporary or transient overvoltage, waveform distortion, voltage sag, and so on.

- The voltage of the power grid exceeds the range

The voltage and frequency of the power grid are not constant and will vary with changes in load and power flow, while the output voltage of the inverter follows the grid voltage. But when the voltage and frequency fluctuations of the power grid exceed a certain range, the inverter will stop working.

- Voltage fluctuations, flicker, and harmonics

In some mechanical processing plants, there are high-power equipment such as cranes, welding machines, gantry milling machines, and some electric arc furnace factories. The electrical energy changes dramatically between equipment start-up and shutdown, accompanied by a large number of harmonics. The harmonics and unbalanced negative sequence components in the power grid will cause fluctuations in the output active power of the photovoltaic system, and the higher the voltage distortion rate of the power grid, the smaller the output active power of the photovoltaic system; It will also output current distortion, and the higher the voltage distortion rate of the power grid, the greater the THD of the output current of the photovoltaic system. When the voltage of the power grid fluctuates violently, the adjustment ability of the inverter is limited, which may cause the photovoltaic inverter to restart frequently. In severe cases, it may cause the power devices inside the inverter to explode due to overvoltage, and the electrolytic capacitors to explode due to overcurrent.

From the above points, the power generation of a photovoltaic power station depends not only on its own power generation performance, but also closely related to its later operation and maintenance. Proper operation and maintenance can not only increase power generation, but also extend the service life of equipment and the power station.