Photovoltaic inverter backflow prevention refers to a technical measure in a photovoltaic power generation system to prevent the power generated by the photovoltaic system from flowing back into the power grid. This technology ensures that the output power of the photovoltaic system does not exceed the actual power demand of the user, thereby avoiding adverse effects on the power grid or potential safety hazards.

The demand scenarios for photovoltaic inverter backflow prevention are mainly concentrated in the following aspects:

- Residential photovoltaic system

In the photovoltaic power generation system installed by residential users, if the power generation of the photovoltaic system exceeds the actual power demand of the household, the excess power may flow back into the grid. This may not only affect the stability of the grid, but also involve complex electricity billing and subsidy issues. Therefore, the photovoltaic system of residential users needs to have a backflow prevention function to ensure the balance between power generation and power consumption.

- Photovoltaic system for industrial and commercial users

Industrial and commercial users usually install large-scale photovoltaic power generation systems. The power demand of such users varies greatly. If the power generated by the photovoltaic system exceeds the power demand in certain periods, it may cause power backflow. Backflow prevention technology can help industrial and commercial users avoid impact on the power grid and ensure the safety and stability of the power grid.

- Microgrid and distributed energy system

In microgrid and distributed energy systems, photovoltaic power generation is an important component. These systems are usually connected to the large power grid and require a high degree of power supply stability. If the power of the photovoltaic system flows back into the large power grid, it may affect the balance and stability of the microgrid and distributed energy system. Anti-backflow technology is particularly important in this scenario to ensure the normal operation of the system.

- Rural power grids and remote areas

The power grid structure in rural and remote areas is relatively fragile and cannot withstand large-scale power backflow. When installing photovoltaic power generation systems in these areas, anti-backflow technology can effectively prevent the power grid from being impacted and ensure the stability and reliability of local power supply.

- Demands of power companies and grid operators

For power companies and grid operators, power backflow will increase the complexity of power grid management, may cause unstable power grid operation, and even cause power failures. Therefore, power companies and grid operators also have a need to ensure that grid-connected photovoltaic systems have anti-backflow functions to maintain the safe operation of the power grid.

- Power regulations and policy requirements

In many countries and regions, power regulations and policies have put forward strict requirements for grid-connected photovoltaic systems, and anti-backflow is one of them. These regulations and policies are intended to ensure the safe and stable operation of the power grid and regulate the grid-connected behavior of photovoltaic power generation systems. Installing anti-backflow equipment is a necessary means to meet these regulations and policy requirements.

- Economic considerations

Through anti-backflow technology, users can better manage the output of photovoltaic power generation systems and avoid economic losses caused by power backflow. At the same time, anti-backflow technology can also optimize the power generation efficiency of the photovoltaic system and improve the economic benefits of the system.

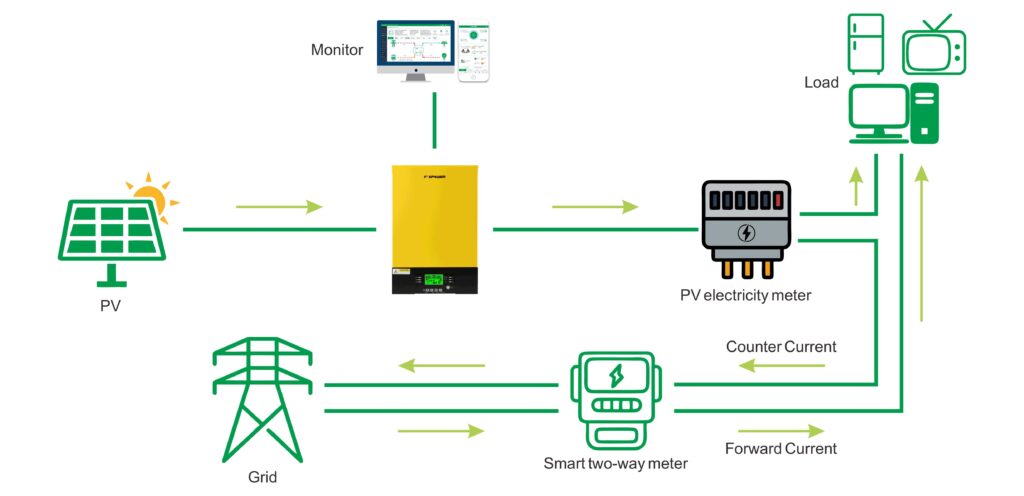

The implementation principle of photovoltaic inverter anti-backflow:

An anti-backflow meter + CT mutual inductor is installed on the main line of the household incoming line to collect the real-time power, current size and direction on the bus. When it is detected that there is current flowing to the grid (reverse current), the anti-backflow meter transmits the reverse power data to the inverter through RS485 communication. After receiving the command, the inverter responds in seconds and reduces the inverter output power, so that the current flowing from the photovoltaic power station to the grid is always kept close to 0, thereby achieving anti-backflow and not sending excess electricity to the grid.

Design and optimization of anti-backflow system

- System architecture design

The architecture design of the anti-backflow system needs to comprehensively consider the scale of the photovoltaic system, the user’s electricity demand and the characteristics of the power grid. The system architecture should include:

- Photovoltaic components: the main source of clean electricity.

- Inverter:converts DC power into AC power and realizes the anti-backflow function.

- Energy storage system: balances supply and demand and avoids backflow.

- Monitoring and control system:monitors the system operation status in real time, adjusts the output power, and prevents backflow.

- Control strategy optimization

Optimizing the control strategy of the anti-backflow system can improve the system operation efficiency and stability. Specific measures include:

- Adaptive control algorithm:dynamically adjust the system output power according to the user’s electricity demand and the photovoltaic system power generation to ensure that the output power matches the user’s demand.

- Distributed control technology:In large-scale photovoltaic systems, distributed control technology is used to divide the system into multiple subsystems, and each subsystem is controlled to avoid backflow in the overall system.

- System reliability and safety

Improve the reliability and safety of the anti-backflow system to ensure that the system operates stably under various working conditions. Specific measures include:

- Redundant design:Redundant design is used on key components (such as sensors, controllers, circuit breakers, etc.) to ensure that the system can still operate normally when a single component fails.

- Fault detection and processing:Establish a complete fault detection and processing mechanism to promptly detect and handle system faults and ensure system safety.

At present, all Foxpower series grid-connected models are equipped with RS485 interface as standard, and all of them can realize the anti-backflow function. In actual project requirements, anti-backflow meters, anti-backflow boxes and other solutions can be flexibly selected according to different scenarios. Among them, anti-backflow meters and anti-backflow boxes involve the problem of communication with photovoltaic inverters, and both must be matched by Foxpower. There is no brand requirement for CT transformers, and they can be flexibly selected according to the bus size and current size on site.